Color Coated Aluminium-Haomei Aluminium

+86-0371-65621391

Add:1103 No.14 Shangwu Outer Ring Rd, New District, Zhengzhou, China.

Email:sale@alumhm.com

The most popular coating aluminum material is PVDF aluminum sheet/ coil, which are widely used in aluminum plastic panel, aluminum ceiling, popo can and electronic products.

Production process of PVDF aluminum sheet/ coil:

Sew the strip to the previous roll

Cleaning the strips

Power brushing

Pre-treating with chemicals

Drying the strip

Use primer to one or both sides

Curing (often only 15 to 60 seconds)

Cooling the strip

Second curing

Cooling down to room temperature

Coated coil rewinding

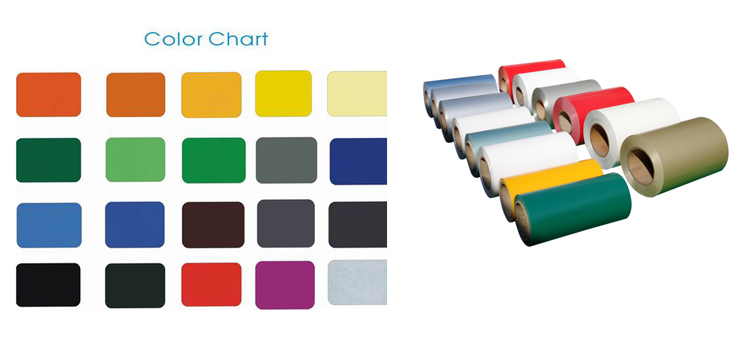

Color Coating aluminum sheet/ Coil is the aluminum sheet/ aluminum coil coated with PE/PVDF paint on surface. The color coated aluminum sheet/ aluminum coil is featured with stable chemical property, good anti-corrosion performance, long warranty period, light weight and so on.

On one or both sides of a metal strip, three separate layers are continuously applied to a coil coating line. These lines vary highly in size, the widths from 18 inches to more than 60 inches and speeds from 100 feet every minute to 700 feet every minute. However, all coated aluminium coils have the same basic process steps. A characteristic organic coated coils are made up by decoilers, cleaning, primer coat application, final coat application, exit accumulation, recoilers, entry strip accumulator, chemical pretreatment and curing.